[WapCar] The cylinder arrangement form refers to the arrangement form of each cylinder of a multi-cylinder engine. In simple words, it is the formation form discharged by the cylinder on the engine.

The common cylinder arrangements forms are mainly inline (L or I), V-type (V), W-type (W), horizontally opposed (H), rotor (R) and VR-type (VR)).

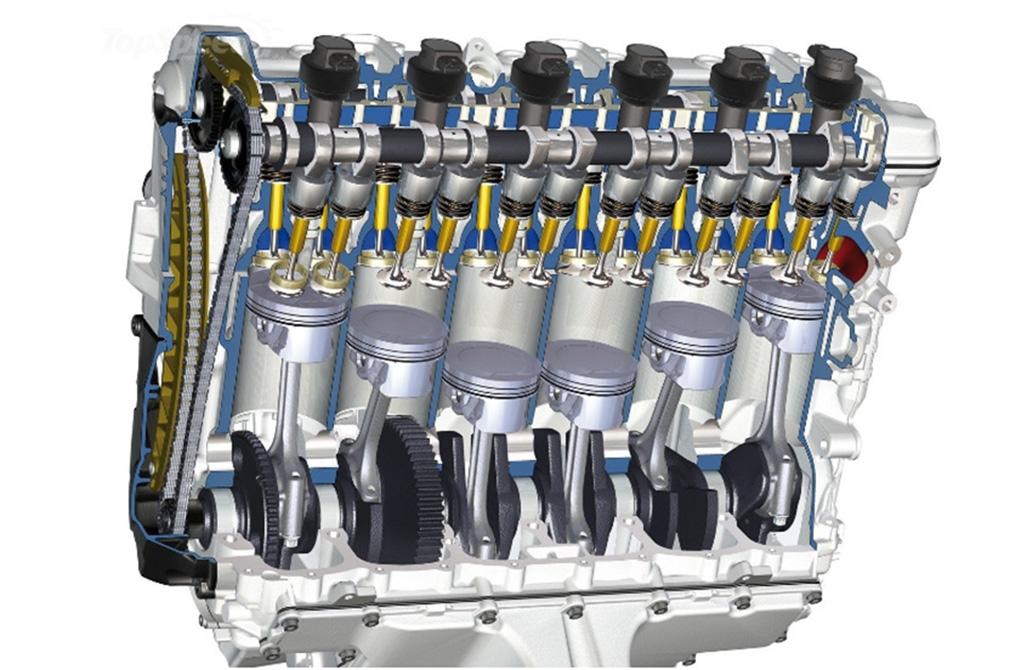

Inline Engine

Inline engines are generally abbreviated as L. For example, L4 means inline 4 cylinders. The inline layout is the most widely used cylinder arrangement today, especially on engines with displacements below 2.5L.

In this layout, all cylinders of the engine are arranged side by side in a plane at the same angle, and used only one cylinder head. At the same time, the structure of the cylinder block and crankshaft is relatively simple, as if the cylinders stand in a column.

Specifically, we generally have four types of L3, L4, L5, L6 (the number represents the number of cylinders).The advantages of this layout engine are compact size, high stability, good low-speed torque characteristics and less fuel consumption, which of course also means lower manufacturing costs.

At the same time, the inline cylinder layout of the engine is also more compact, can adapt to a more flexible layout, and is also convenient for arranging supercharger devices. But its main disadvantage is that the power of the engine itself is low, and it is not suitable for vehicles with more than 6 cylinders.

V-type Engine

The so-called V-type engine simply means that all cylinders are divided into two groups, and the adjacent cylinders are arranged at a certain angle (the angle between the center lines of the left and right rows of cylinders γ<180°), so that the two groups of cylinders form an angle plane, When viewed from the side, the cylinder is V-type (the usual angle is 60°), so it is called a V-type engine.

Compared with the in-line layout we introduced above, the V-type engine shortens the length and height of the body, and the lower installation position allows designers to design a body with a lower drag coefficient. At the same time, it benefits from the opposed arrangement of cylinders. It can also offset part of the vibration and make the engine run more smoothly.

For example, some mid-to-high-end models pursuing comfortable and smooth driving experience still insist on using large-displacement V-type layout engines, rather than the more technologically advanced "small-displacement in-line layout engine + supercharger" power combination.

In a nutshell: we can understand that the engine cylinder adopts a V-shaped layout, which can be said to overcome some of the disadvantages of traditional in-line layout at the structural level. But again, the precise design makes the manufacturing process more complicated, and at the same time, it is not convenient to install other auxiliary devices due to the large width of the body.

W-type Engine

Many people think that just as the cylinders of a V-engine are arranged in a V-type, the cylinders of a W-engine must also be arranged in a W-type. Actually not, it is only approximately W-type arrangement. Strictly speaking, it should be a V-type engine, and at least a variant of the V-engine. W-type engine is the exclusive engine technology of German Volkswagen.

Compared with the V-type engine, the W-type can make the engine shorter, and the crankshaft can also be shorter, which can save the space occupied by the engine, and the weight can also be lighter, but its width is larger, making the engine compartment More full.

The biggest problem with the W-type engine is that the engine is divided into two parts from a whole, which will inevitably cause great vibration during operation. In response to this problem, Volkswagen designed two counter-rotating balance shafts on the W-type engine, so that the vibrations of the two parts cancel each other internally.

Horizontally Opposed Engine

As mentioned in the introduction of the cylinder V-type engine above, the included angle formed by the V-type layout is usually 60° (the angle between the center lines of the left and right rows of cylinders γ<180°), while the cylinder angle of the horizontally opposed engine is 180°.

However, the manufacturing cost and process difficulty of the horizontally opposed engine are quite high, so currently only Porsche and Subaru are in use in the world.

Advantage

The biggest advantage of the horizontally opposed engine is its low center of gravity. Because its cylinder is "flat", it not only lowers the center of gravity of the car, but also makes the front of the car flat and low. These factors can enhance the driving stability of the car.

At the same time, the horizontally opposed cylinder layout is a symmetrical and stable structure, which makes the engine run smoother than the V-type engine, and the power loss during operation is also minimal. Of course, the lower center of gravity and balanced distribution also bring better handling of the vehicle.

Disadvantage

Then why don't other manufacturers develop horizontally opposed engines? In addition to the complexity of the horizontally opposed structure, problems such as oil lubrication are difficult to solve.

The horizontal cylinder will cause oil to flow to the bottom due to gravity, so that one sida of cylinder cannot be sufficiently lubricated. Obviously both Porsche and Subaru have solved many technical problems well, but the high-precision manufacturing requirements have also brought higher maintenance costs, and due to the wider body, it is not conducive to the layout.

Rotary Engine

Compared with the common L-type and V-type cylinder layout, many friends may be unfamiliar with the triangular rotor engine. The rotary engine, also known as the Miller cycle engine, was invented by the German Feigas Wankel, and later this technology was acquired by Mazda.

We all know that: in the traditional cylinder reciprocating engine, the piston makes reciprocating linear motion in the cylinder when it is working, and in order to convert the linear motion of the piston into rotary motion, a crank connecting rod mechanism must be used.

The rotary engine is different, it directly converts the combustion and expansion force of combustible gas into driving torque. Compared with the reciprocating engine, the rotary engine cancels the useless linear motion, so the rotary engine of the same power is smaller in size, lighter in weight, and lower in vibration and noise, which has greater advantages.

Working Principle

When the triangular rotor rotates, the inner ring gear centered on the center of the triangular rotor meshes with the gear centered on the output shaft center. The gear is fixed on the cylinder and does not rotate. The ratio of the number of teeth of the inner ring gear to the gear is 3:2. The above motion relation makes the motion track of the apex of the triangular rotor (that is the shape of the cylinder wall) like "8" shape.

The triangular rotor divides the cylinder into three independent spaces. The three spaces complete air intake, compression, work and exhaust respectively. The triangular rotor rotates for one revolution and the engine ignites and performs work three times. The rotor of a rotary engine does work every time it rotates.

Compared with a general four-stroke engine that only does work once every two revolutions, it has the advantage of high power-to-volume ratio (smaller engine volume can output more power). Besides, due to the axial operating characteristics of the rotor engine, it can achieve high running speed without the need for precise crankshaft balancing.

The whole engine has only two rotating parts. Compared with a general four-stroke engine with more than 20 movable parts such as intake and exhaust valves, the structure is greatly simplified, and the possibility of failure is greatly reduced.

In addition to the above advantages, the advantages of rotary engines also include small size, light weight, and low center of gravity. The corresponding disadvantage is that the engine is easy to air leakage due to wear of the oil seal material after a period of use, which increases fuel consumption. Additionally, its unique mechanical structure also makes such engines difficult to maintain.

VR Engine

The VR engine is also an exclusive product of Volkswagen. In 1991, Volkswagen developed a V6 2.8L engine with an angle of 15°, called VR6, and installed it on the third-generation Golf. This kind of engine is compact, the width is close to the inline engine, and the length is not much longer than the inline 4-cylinder engine.

The cylinder Angle of the VR engine is very small, the two cylinders are nearly parallel, and the holes in the spark plug of the cylinder cover are almost in a straight line. The VR engine is characterized by its very small size, so it is very suitable for the front engine platform of the Volkswagen car series, because the Volkswagen front engine front-wheel drive chassis is a vertical design, and the engine is before the front axle, so the engine cannot be too long. Otherwise it is difficult to arrange the front suspension.

This engine is very compact,although it is a V-cylinder engine, because the two cylinders are very close to each other, only one cylinder head is needed. It is much cheaper than the 90-degree and 60-degree V6 (because the ordinary V-cylinder engine Two cylinder heads must be machined. If it is a DOHC V-cylinder machine, 4 camshafts need to be machined, so the cost is very high).

But the actual situation is that for the V-type 6-cylinder engine, the angle of 60 degrees is the optimal design, which has been proved by numerous scientific experiments. Therefore, most V6 engines use this layout. However, in order to put down the V6 engine in a smaller space, the Volkswagen Group has developed a 15-degree angle and a smaller VR6 engine.

From the perspective of power parameters, it is not inferior to the ordinary V6 engine, but it exposed obvious jitter problems at the beginning of development. Although the problem has been significantly improved through a series of balance and stabilization measures, it still cannot go beyond changing its own structural characteristics. Just like the vibration of an ordinary in-line engine is usually greater than that of a V-type engine, the VR6 has a smaller angle from the structure. It determines its vibration will be greater than V6.