[ WapCar ] We can regard the electric motor as the "internal combustion engine" of the electric vehicle, the electric motor is a machine with high energy conversion efficiency. Compared with the 30% working efficiency of the internal combustion engine, the electric motor is usually above 85%, and the greater the power, the higher the work efficiency, and the efficiency of large motors can even reach 98%.

According to the type of power supply, it can be divided into DC motor and AC motor. According to the structure and working principle of the motor, it can be divided into DC motor, asynchronous motor and synchronous motor.

| Performance characteristics of 4 typical motors | |||||

|---|---|---|---|---|---|

| Performance and type | DC motor | AC motor | Permanent magnet synchronous motor | Switched reluctance motor | |

| Speed range/rpm | 4000~6000 | 12000~20000 | 4000~10000 | >15000 | |

| Power density | low | medium | high | Higher | |

| Motor weight | heavy | medium | light | light | |

| Motor volume | big | medium | small | small | |

| Reliability | general | good | excellent | good | |

| Structural robustness | poor | good | good | good | |

| Controller cost | low | high | high | general | |

DC motor

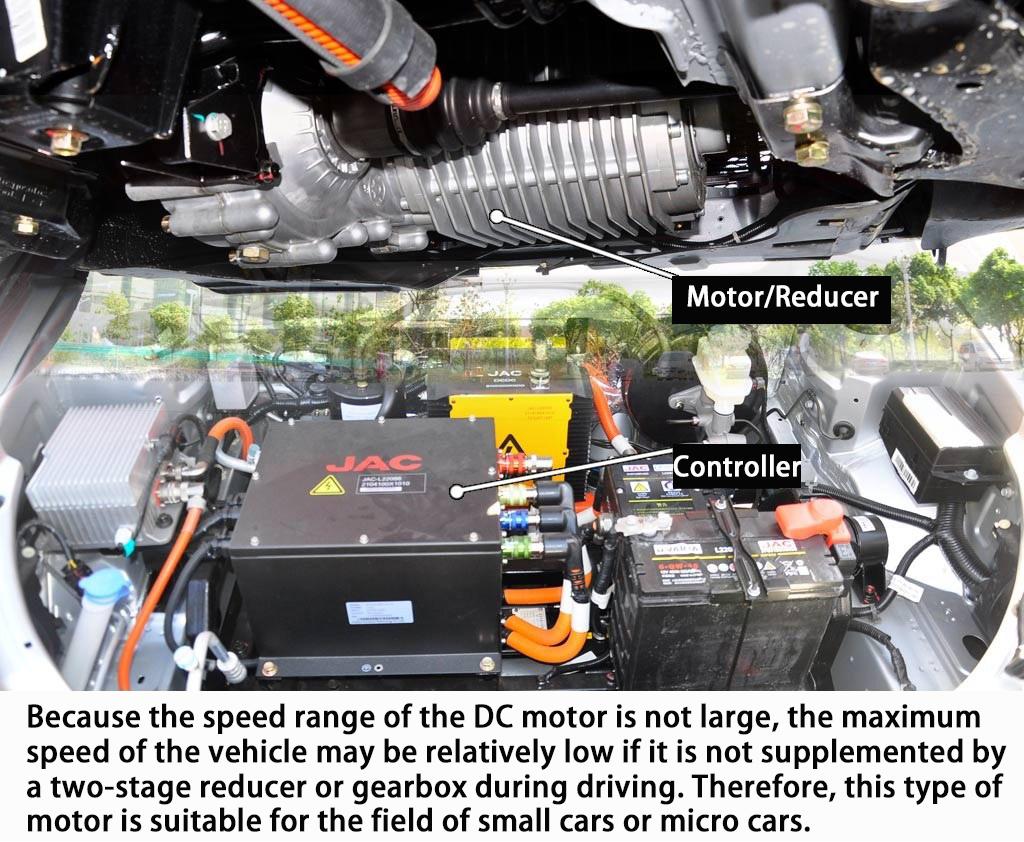

The battery stores electrical energy, and the electrical energy is transmitted from the battery output through the converter to the motor in the form of direct current. DC motors are divided into brushed DC motors and brushless DC motors. Brushless DC motors are replaced by brushless DC motors due to inconvenient maintenance, brushless DC motors have become the most common type used in entry-level electric vehicles.

According to the technical requirements of electric vehicles for electric motors, DC motors can meet the basic needs of electric vehicles. In addition, the brushless DC motor does not require users to consider its maintenance during the use of the car, and based on this feature, the brushless DC motor has become the first choice for entry-level electric vehicles.

DC motors also have some drawbacks, its speed range is not wide, and the maximum speed is only about 6000rpm, such speed attributes are difficult to meet the working conditions of electric vehicles. Therefore, some manufacturers make up for the shortcomings of the DC motor in terms of speed by matching it with a two-stage reducer or a CVT gearbox with a certain transmission gear ratio range. Obviously, such a technical structure has an adverse effect on the design of the vehicle in terms of space layout and weight control. Of course, it is also possible to match the electric motor with a single-stage reducer, but the dynamic performance of the vehicle and the maximum speed will be affected.

Asynchronous motor

First, let's understand what an asynchronous motor is: asynchronous motor is also called induction motor. It is an AC motor that generates electromagnetic torque by the interaction of the air gap rotating magnetic field and the induced current of the rotor winding, thereby realizing the conversion of electromechanical energy into mechanical energy.

Frequency conversion speed regulation is the first function of the electric motor, because the wheels of a pure electric vehicle are driven by a transmission mechanism composed of an electric motor and a differential. The speed range of the electric motor itself can meet the driving needs of the vehicle. Therefore, from the perspective of technical structure, the gearbox is no longer a necessary device for the entire power system. However, in terms of the performance of variable frequency speed regulation, higher requirements are put forward on the motor. In addition, reversing is also a problem often encountered in daily driving, so the motor is also required to be able to switch between forward and reverse states freely.

The asynchronous motor has the ability of variable frequency speed regulation, and its effect is equivalent to the relatively linear correspondence between the engine speed and the vehicle speed when the vehicle equipped with a continuously variable gearbox is accelerating. As for the reversing problem mentioned above, the asynchronous motor can also be easily satisfied by its own forward and reverse switching.

It is also easier for asynchronous motors to realize kinetic energy recovery. When the vehicle is coasting or braking, the wheels reverse to drag the motor to rotate, under this working condition, the motor can generate electricity and recover the electrical energy into the battery, thereby extending the vehicle's cruising range.

Functionally, it can meet the technical requirements of electric vehicles, but its own structure is not complicated, which brings advantages such as sturdiness and durability, stable working conditions, and easy-to-control costs.

Permanent magnet synchronous motor

A permanent magnet synchronous motor is a synchronous motor that is excited by permanent magnets to generate a synchronous rotating magnetic field. The permanent magnet acts as a rotor to generate a rotating magnetic field, the three-phase stator winding reacts through the armature under the action of the rotating magnetic field to induce a three-phase symmetrical current.

The structure of the permanent magnet synchronous motor is similar to the DC motor mentioned above, so that it can have the characteristics of simple structure, reliable operation, high power density, and good speed regulation performance of the brushless DC motor. At the same time, since the drive mode of the permanent magnet synchronous motor is different from that of the DC motor, the permanent magnet synchronous motor is better in terms of noise and control accuracy.

The use of permanent magnet synchronous motors is also helpful to the riding comfort of electric vehicles. Under normal circumstances, we regard the quietness of the passenger compartment as one of the factors to measure the comfort of a car. For general users, this measurement standard is also applicable to electric vehicles. Most of the current electric vehicles only provide a one-stage reducer. Therefore, the speed of the electric motor is relatively high, It is affected by factors such as the driving mode of the electric motor, the assembly accuracy and the matching between various components. The noise emitted by the electric motor when the vehicle is running may affect the interior of the vehicle The ride comfort of the occupants. Of course, we cannot deny the role of vehicle sound insulation engineering, but only to evaluate the control of noise sources, permanent magnet synchronous motors still have certain advantages. In addition, its volume is smaller, in other words, the layout is more flexible, and the lighter weight also contributes to the weight of the vehicle.

Switched reluctance motor

Switched reluctance motor is a motor with great development potential. In addition to the advantages of simple structure, sturdiness and durability, reliable work, and high efficiency, its speed regulation system has more controllable parameters and economic indicators than the above motors. The power density is also higher, which means that the motor is lighter and more powerful, and can achieve 100% starting torque when the current reaches 15% of the rated current. Besides, the smaller size also makes the design of the electric vehicle more flexible, which can contribute more space to the vehicle. More importantly, the cost of this motor is not high.

Although the structure of the switched reluctance motor is simple, the design of the control system is relatively complicated, especially in the research and development stage, it is difficult to establish an accurate mathematical model for the existing technology. In the actual operation process, the noise and vibration emitted by the electric motor itself cannot be "tolerated" by the electric vehicle, these two points are especially obvious when the load is running. In summary, this type of motor may be widely used in the field of electric vehicles under the premise that technology optimization can overcome fatal injuries in the future, which can help the range of electric vehicles to increase.

The in-wheel motor, which was born 100 years ago, is still in the conceptual stage. At present, many supporting manufacturers are able to come up with design solutions for in-wheel motors and drive axles. However, few manufacturers are able to adopt it, and the excessive burden on the unsprung quality of the in-wheel motor is one of the reasons that hinder its development.